Efficient brick management is an important part of quality refractory installation. An ideal system will do three things –

- Decrease material handling. Handling leaves small nicks and chips in the brick surface, negatively impacting quality.

- Increase safety by minimizing the physical handling of refractory. This results in less strain on employees and fewer minor injuries such as cuts, scrapes and bruises.

- Provide fast material delivery. This ensures there’s no unnecessary interruption for the bricking crew.

Selecting the right tools to optimize brick delivery depends a lot on the size of the kiln. That’s why Bricking Solutions has developed several brick management options. Let’s see which one is the best fit for your operation.

Bricking Machines

For large diameter kilns, those 4 meters (13 feet) and up, the most effective tool for brick management will always be a skid steer, forklift or other small equipment. Being able to drive a full pallet of bricks from the staging area to the bricking machine is unquestionably the fastest delivery method with minimal brick handling.

This type of delivery can be used with both our Kiln Bedding Cart and EZ Flexx50 Bricking Machine for fast, efficient material management.

Additionally, our new Stair-Stepped Bricking Machine makes this process even more efficient for masons who prefer their bricks delivered from the keying side of the machine. This design provides additional clearance under the machine, allowing crews to drive support equipment underneath to deposit refractory materials. In situations where the bricking machine is following the bedding cart, brick can be easily accessed by both crews for increased productivity.

Port-A-Trac

Not every kiln is large enough to operate support equipment. In these situations, masons must look for alternative systems that still provide for minimal brick handling, increased safety and faster delivery.

Our Port-A-Trac is a lightweight, modular system that allows two people to transport a full pallet of brick up kiln — and under the bricking machine — at approximately 2.5 meters per minute (8 feet per minute). The system increases material transport efficiency by more than 20% compared to roller conveyors, which might take up to an hour and a half with a crew of five. It also minimizes material handling, allowing the brick to be transported as a pallet, which avoids potential damage.

The system comes with two 1.12-by-1.1-meter (44.25-by-43.5-inch) carts that are easy to maneuver in the tight space of smaller kilns. The carts can be loaded together and pulled with a winch or operated separately, giving crews the opportunity to reload one cart on the burn floor while the bedding crew takes brick from the other to increase efficiency.

Conveyors

Despite the benefits of transporting kiln brick in a pallet, there are situations where it must be moved individually, such as delivering it from the kiln floor to the deck of the bricking machine or feeding it to crews in very narrow kilns. In these situations, mechanical conveyors provide a more efficient solution than roller conveyors or so called “bucket brigades.”

Our Incline Conveyor uses an electric motor to transfer brick and refractory from the kiln floor to the bricking machine with minimal effort. It can be used with any size bricking machine to deliver 15-20 bricks per minute. Using an incline conveyor eliminates the need for workers to carry materials up and down bricking machine ladders or pass materials overhead, both dangerous and physically demanding actions.

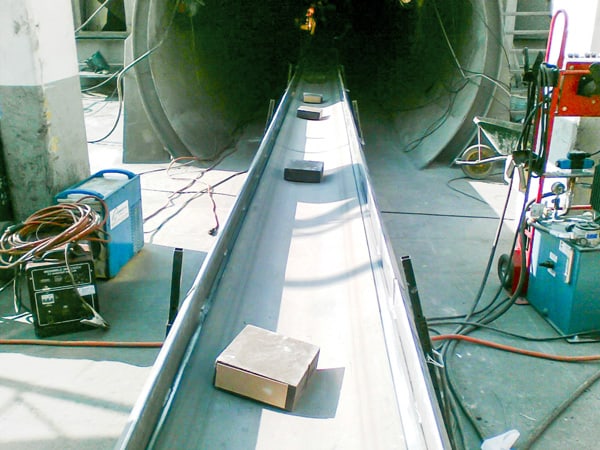

For moving brick up kiln in narrow vessels — as well as taking debris out — our Hydraulic Conveyors provide a portable, easy-to-use solution. With a small crew, the system can be set up in as little as one to two hours, depending on length and site conditions. A 5-horsepower hydraulic drive moves up to 907 kilograms (2,000 pounds) in either direction at a rate of 45 meters per minute (150 feet per minute). This allows crews to remove material twice as fast as manual methods and a two-person crew can bring a full pallet of brick into the kiln in less than 10 minutes.

Refractory Brick Delivery for Any Situation

Inefficient refractory delivery can derail installation, so finding a method that fits your situation is important to overall quality. Many of the solutions here can be tailored to meet site specific requirements. Contact our team today to find the brick management system that’s right for your facility.