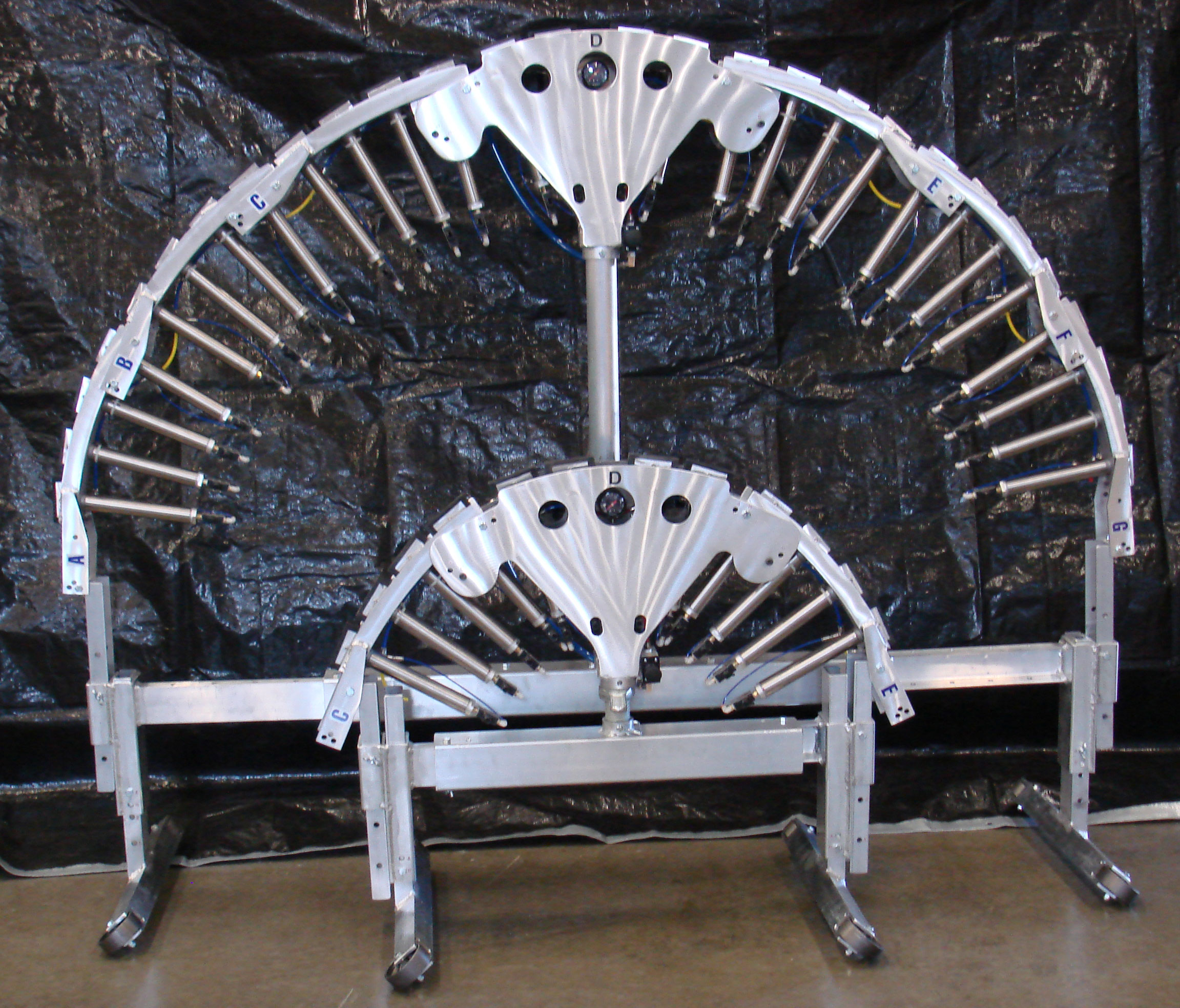

Bricking Machines

The safest, lightest & most efficient bricking rigs in the industry.

We have been manufacturing bricking machines worldwide for over 50 years. Because Bricking Solutions specializes in bricking machines, we can build any size machine for your rotary kiln (max. 2M range). Our bricking machines are the safest, most efficient, and lightest rigs in the industry because we use the highest strength and highest quality aluminum.