Quality bricking machines are the key to successful installation practices. However, we understand that, in the short term, choosing a bargain machine and cutting upfront costs is tempting — especially since bricking machines have a limited purpose. Why would you invest in a premium product for occasional use?

Once you start adding up costs, though, the reasons to choose quality equipment become clear. Plants can lose upwards of half a million dollars per installation as a result of using a low-cost, low-quality bricking machine. Bricking Solutions’ custom bricking machines negate these costs and provide a quick turnaround for ROI. To make the right choice, here are a few key things to look for to determine which bricking machine is best for long-term use and will result in the lowest total cost of ownership.

1. Quality Manufacturing

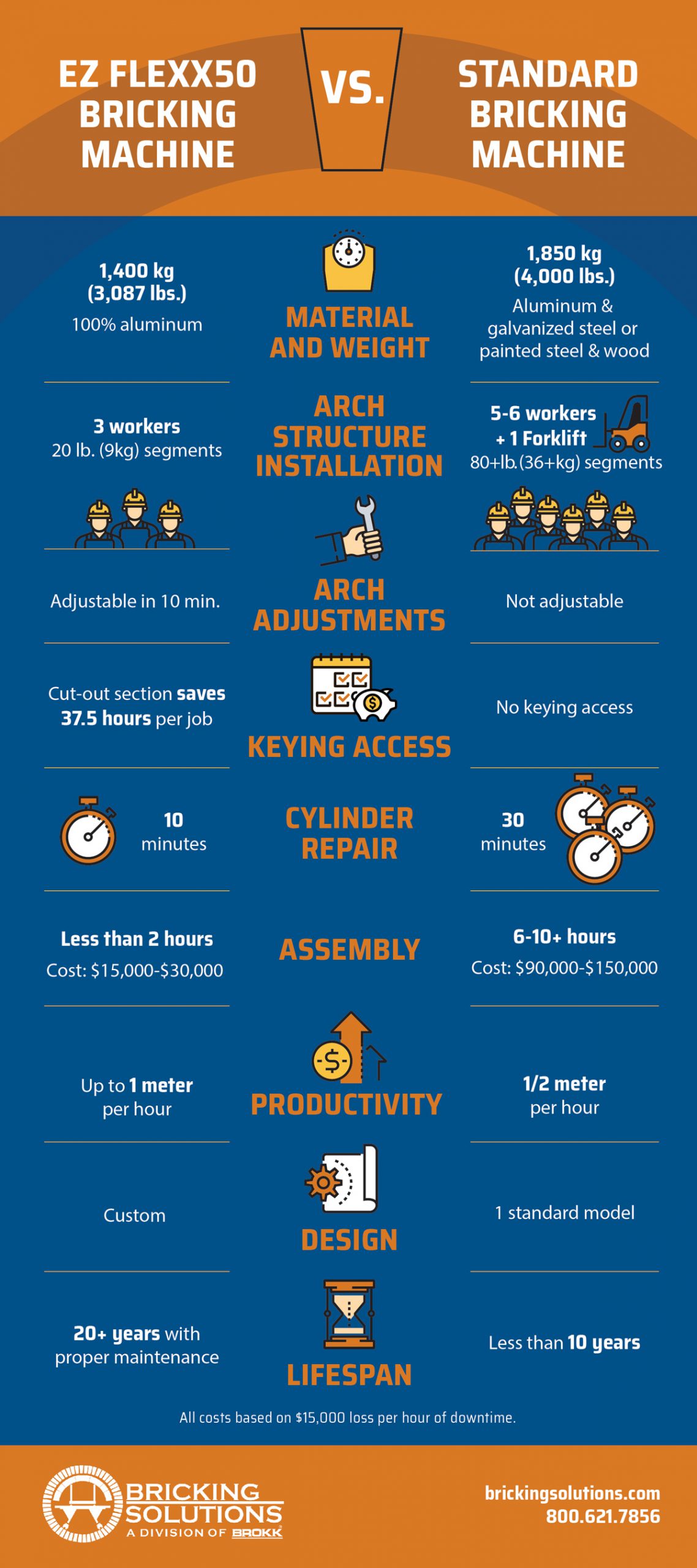

Purchase price is the first thing most people look at for equipment. The low price tag is appealing, but these prices are a direct result of manufacturing practices. Bargain bricking machines constructed from aluminum and galvanized steel or painted wood and steel generally weigh around 1,850 kilograms (4,000 pounds). Setup takes five to six crew members, a forklift and 6 to 10 hours. Assuming a $15,000 loss per hour of downtime, that’s at least $90,000 just for setup. Plus, the lower-quality materials are more prone to premature cracking and damages. The lifespan of these machines is no more than a decade, sometimes three years or less.

When lost profits are on the line, a quality bricking machine just makes sense. We construct our bricking machines of strong, lightweight 6061-T6 aircraft-grade aluminum that weighs in at only 1,400 kilograms (3,087 pounds). A four-person team can easily set it up in just 60 to 90 minutes. With the same cost per hour, a quality bricking machine setup costs only $15,000 to $22,500. Even with the slowest possible setup time, we see savings of up to $67,500. The superior manufacturing quality means the lifespan of one of our bricking machines is a minimum of 20 years.

2. Productive Design

A well-designed bricking machine isn’t just a machine made of quality materials, though. Intuitive manufacturing and ergonomic design significantly improves installation productivity and saves thousands of dollars in labor with a single use.

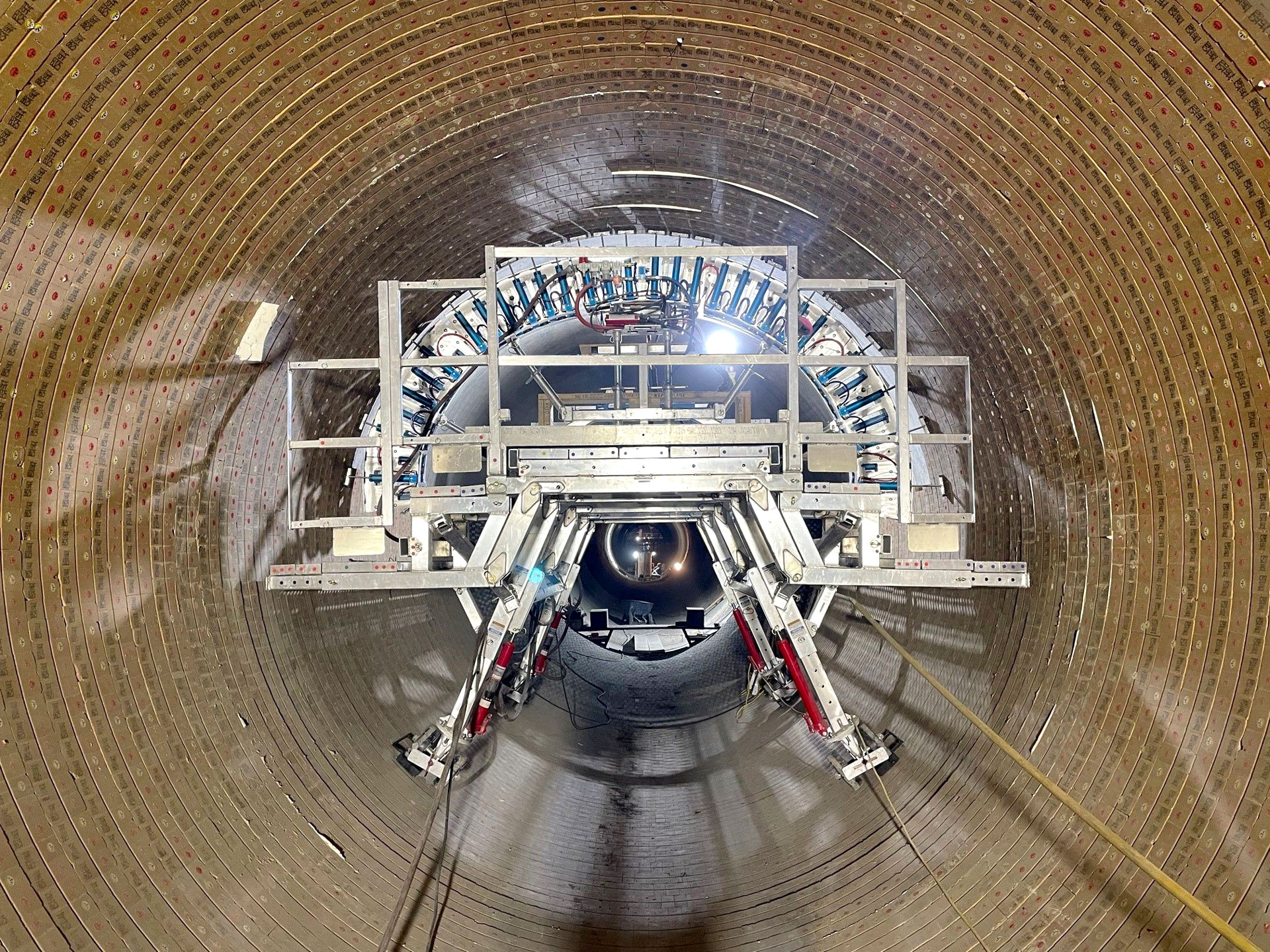

Arch design is one example of intuitive manufacturing. Bargain bricking machines only have a single arch. We design our bricking machines with a double arch so crews can install a second ring of brick while the first is being keyed, doubling productivity.

Keying access is another design feature to watch for. High-quality bricking machines feature a cut-away section in the front arch that allows keying masons to see the previously keyed ring as a guide when placing bricks.

3. Custom Engineering

Quick installation and ergonomic design mean nothing if the installation quality is poor and results in refractory failure. To achieve tight, high-quality installation, the bricking machine needs to fit the kiln and account for distortions in the shell. Bargain machines are manufactured in a one-size-fits-all approach, leaving the potential for air gaps between the shell and brickwork and interlocking rings.

Bricking Solutions’ bricking machines are custom engineered for your specific kiln. The double arch is designed to be fully adjustable to the interior of the kiln. If there are irregularities, the arch holds each brick firmly against the kiln shell until the key brick is installed, ensuring a tight fit. Another critical feature on our machines is the cut-away section for keying. Brick masons have a clear view of the previously keyed ring to use as a guide. They’re then able to see any open space between bricks to correct it.

The Bottom Line

When you start looking at the long game, it becomes clear the low-quality machine is really no bargain. Spending more up front is the long-term bargain when you consider the lifespan of the machine, the productivity gains and the advantages of long-lasting installations. To learn more about custom-designed bricking machine solutions and the total cost of ownership associated with them, contact our experts today.