No one has time to mess around during shutdown. Refractory maintenance is tough enough without battling outdated equipment and inefficient setups. At Bricking Solutions, we believe there is a better way and build the tools that streamline setup, improve safety and ensure quality refractory installation.

For example:

Problem: Poor ramp design or fit

Accessing the kiln can be challenge if the ramp is difficult to set up or is ill-fitting. Some of the issues we’ve seen include ramps that aren’t properly engineered, leading to over-engineered steel ramps. Heavy steel ramps can take a long time to setup — as long as 6-10 hours. They can also increase the safety issues associated with ramp installation.

A Better Way: Custom-Engineered Ramps

A high-quality, custom-designed ramp is a safer, smarter and more economical solution. We can engineer a ramp tailored for your load requirements, approach angles and sill heights. Made from 6061-T6 aircraft-grade aluminum, our ramps have the strength of steel at just one-third the weight. In addition, our standard ramps support up to 15,000 pounds (6,804 kg).

Even better? Our custom ramps can be installed in as little as 1.5 hours.

Problem: Imperfect brick installation

Traditional installation methods — like pogo sticks — run a high risk of failure due to improper installation. This results in a domino effect of failing brick rings and air gaps left between the brickwork and shell, which result in hot spots. Minimizing air gaps, interlocking rings and loose bricks extends the lifespan of the brick lining and can drastically reduce unscheduled maintenance.

Older installation methods also require the kiln to be rotated, which makes it difficult to maintain radial alignment of the brickwork. Misaligned brick can’t uniformly absorb pressure, which can lead to brick failure. Spiraling and twisting account for as many as 50% of unscheduled outages, which are almost always tied to the installation method.

A Better Way: A Quality Bricking Rig

A quality bricking machine with advanced design goes a long way toward preventing issues. The arches hold the brick tight against the kiln shell via rubber bumpers to ensure a tight fit with no gaps or loose brick. Our dual arch system permits a second ring of brick to be installed while the first is being keyed.

This design features a cut-away section on the front arch that provides an unobstructed area to place key bricks. Machines without this feature force installers to try to find other ways to reach around the arch, reducing installation speed and, possibly, quality. Additionally, the pneumatic arch systems provide superior quality results that can extend the longevity of refractory by as much as 25%.

Our meticulously designed bricking machines, manufactured with 6061-T6 aluminum, also improve safety and efficiency. Other options are commonly made from a combination of galvanized steel and aluminum, making them heavy and cumbersome to handle. Our rigs feature pin-together construction with heavy-duty hitch pins and clevis pins to improve setup and teardown speed. They can be assembled in just 60 to 90 minutes by an experienced crew.

Problem: At-Height Installations

Vertical vessels that need rebricking offer their own unique challenges. Erecting a scaffolding system is time-consuming, with setup taking as long as week — even with an experienced crew.

Another issue is that scaffolding can only safely reach a certain height. One refractory maintenance contractor, for example, found that they could only rebrick half of a 12.2-meter (40-foot) vessel safely with swing scaffolding. If they went any higher, the entire structure would destabilize, making it unsafe for crews.

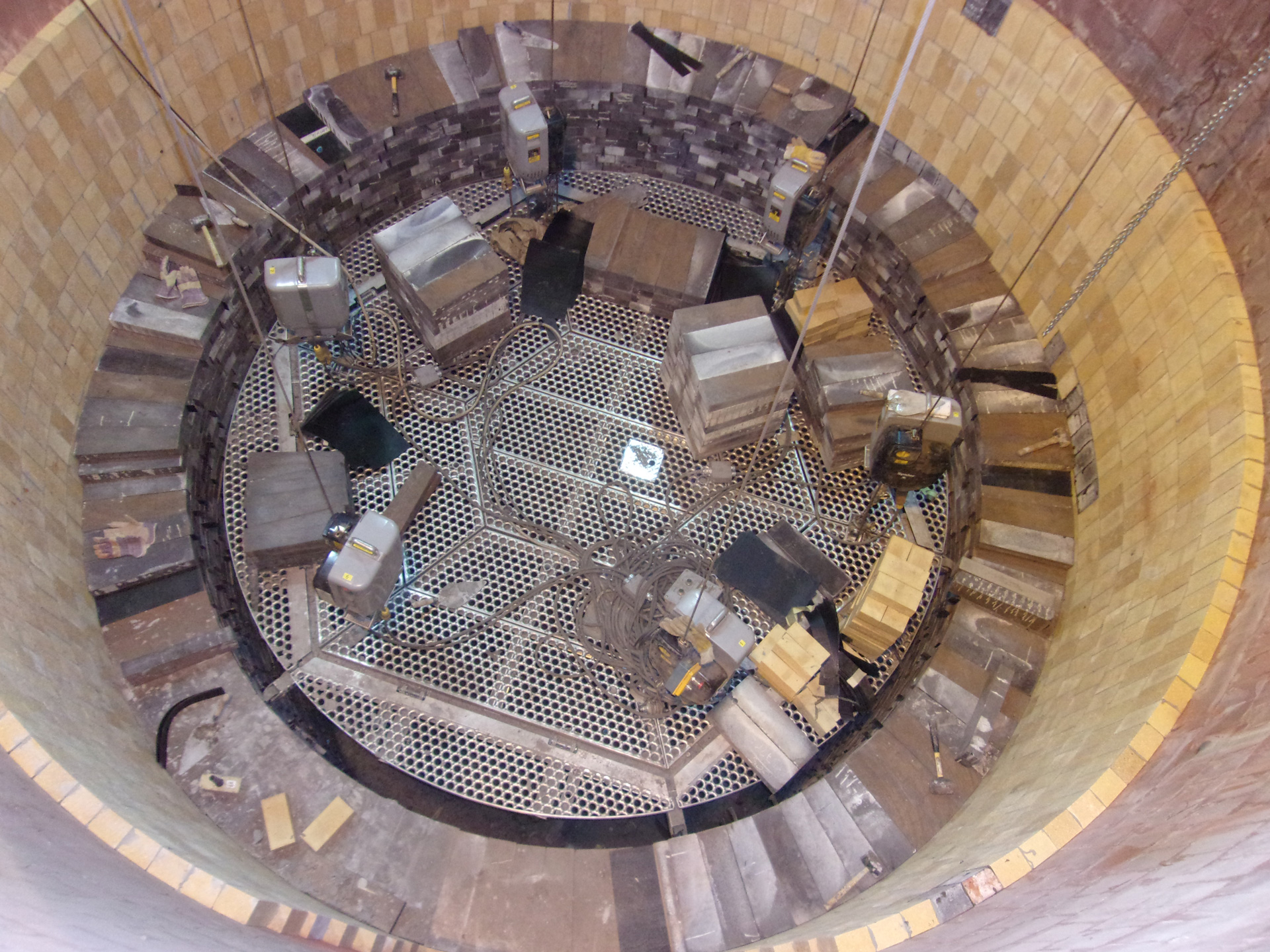

A Better Way: A Custom-Engineered Suspended Platform

For many processing facilities, a suspended platform is the best option for at-height work. The previously-mentioned contractor was able to complete the other half of the installation by working with us to create a custom suspended platform for the smelter, allowing the crew to finish the project in a timely manner with multiple work fronts.

Custom-engineering means the platform is fitted to the diameter of the vessel, up to 6.7 meters (22 feet), which provides the crew with 360-degree access to the vessel walls. The suspended platforms feature ample space for personnel, tools and materials. Our suspended platforms also allow crews to adjust the size of the platform by up to 1 meter (3.3 feet) while suspended by changing the outer panels. This results in better accessibility and easy transition between different widths of vessels, such as cyclones.

Using a suspended platform eliminates lengthy setup times and the safety risks that come with scaffolding. While the suspended platform does require initial site preparation, it never needs to be done again once it is completed. Our platforms typically require six holes large enough to insert a 50-millimeter (2-inch) ID pipe to be inserted into the vessel, which can be plugged when not in use. Some vessels also require support beams that span the gap between roof beams and spread the platform’s load.

In some vertical vessels with a clear, leveled surface, assembly can be completed on the bottom of the vessel. The modular pieces also can fit through access holes as small as 0.55 meters (22 inches) in diameter. Each piece weighs 18 kilograms (40 pounds) or less, making them easy to maneuver into place. Pin-together construction provides flexibility when raising or lowering the platform.

Ready to streamline your next shutdown? Contact us to discuss your refractory maintenance challenges.