- All

- Articles

- BBS Technical Services

- Bedding Cart

- BrickCheck

- Bricking Machines

- Bricking Solutions

- Brokk Cart

- Expand-O-Ring

- EZ Flexx

- Fork Truck Bracket

- Incline Conveyor

- Kiln Ramps

- News

- Port-A-Trac

- Safety Cages

- Split Bedding Cart

- Suspended Work Platform

- Torpedo Ladle

- Vertical Vessels

A Project That’s a Decade in the Making

Refractory maintenance in a metal processing facility is already a big project, which only gets bigger when the furnace in question is 40 feet tall and 22 feet in diameter. In 2014, Dave Drorbaugh II worked as lead project manager at a metal processing facility. That year, they initiated a major shutdown to rebrick half [...]

Boosting Refractory Brick Confidence with BrickCheck

Refractory brick testing is an important factor in determining when brick replacement is required for furnaces, cyclones, kilns and other vessels. Having a monitoring device on hand makes the process easier, giving operations the ability to check brick thickness whenever downtime occurs. Brian Robert, process engineer at the Stockerton, Pennsylvania, facility of Buzzi Unicem USA, [...]

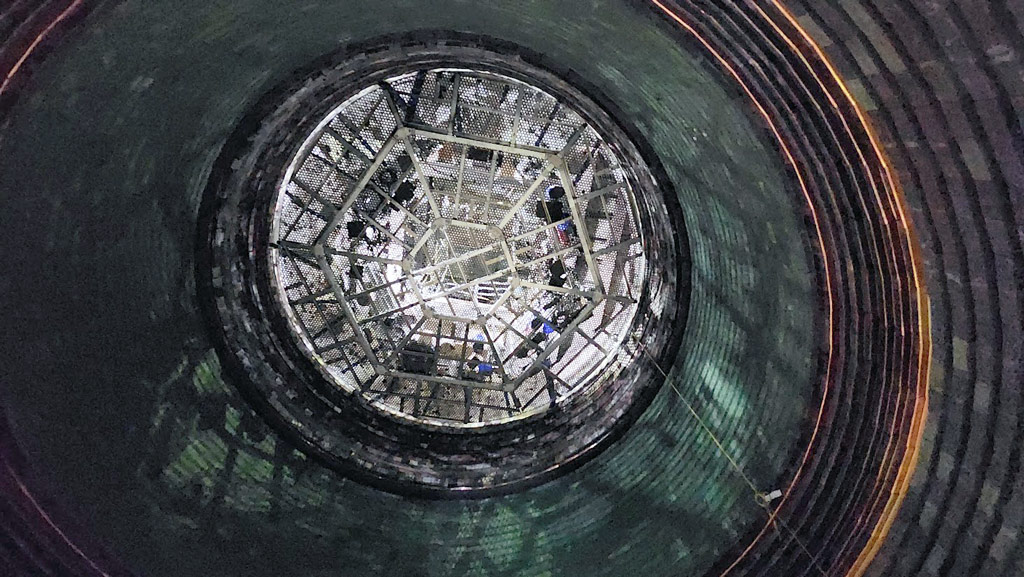

6 Reasons to Use a Suspended Platform for Vertical Vessel Maintenance

A suspended platform offers a number of advantages over scaffolding for vertical vessel maintenance. See our guide for key differences.

Creative Solutions for Refractory Maintenance

Ever wish someone could fix your problems? We can’t do much about a bad haircut or a leaky roof, but when it comes to refractory maintenance, we love a good challenge. Whether it’s an access, installation or safety challenge, we work with customers to design and build custom solutions. Here are a few examples of [...]

Bricking Solutions Introduces BrickCheck

Bricking Solutions, a full solution provider of refractory installation equipment, introduces BrickCheck. BrickCheck measures the thickness of refractory lining inside industrial furnaces, ovens and kilns quickly and easily in a nondestructive way after calibration. The readings can be used to ensure smooth operation of a vessel and help plan future maintenance in any facility that [...]

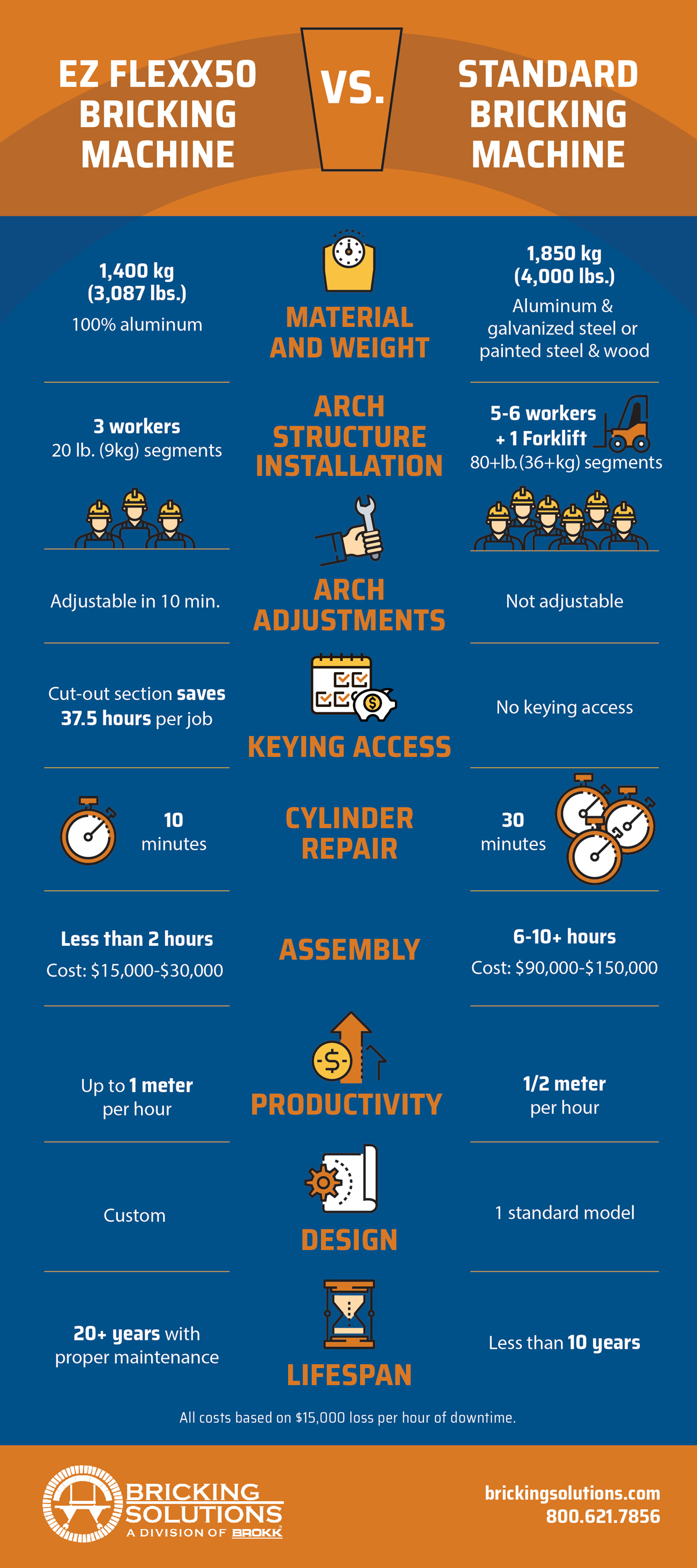

Quality Bricking Machines: The Total Cost of Ownership Advantage

Quality bricking machines are the key to successful installation practices. However, we understand that, in the short term, choosing a bargain machine and cutting upfront costs is tempting — especially since bricking machines have a limited purpose. Why would you invest in a premium product for occasional use? Once you start adding up costs, though, [...]

Split Bedding Cart to Added Refractory Maintenance Lineup

Bricking Solutions, a full solution provider of refractory installation equipment, introduces a bedding cart with a split deck for increased access to brick during refractory brick installation. The Split Bedding Cart features dual decks rather than a single deck in order to provide clearance for a forklift or skid steer. Along with allowing equipment to [...]

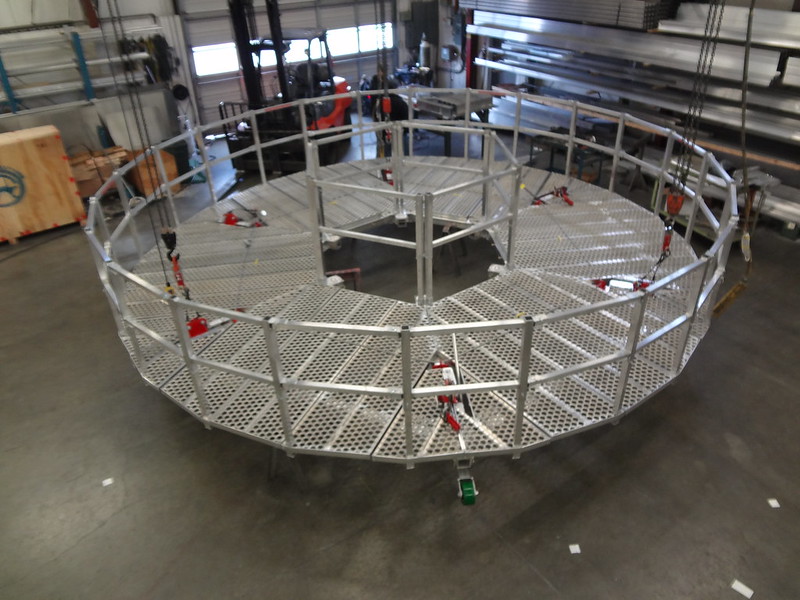

3 Common Questions About Our Suspended Platform

Suspended platforms are game changing when you have vertical vessels to maintain. They eliminate the lengthy setup times and safety risks that come with scaffolding. One of our customers, a sugar beet processing facility, could only complete a fraction of the major repairs needed when working for the full length of their maintenance cycles — [...]

Revolutionize Your Refractory Maintenance Process

Cement facilities know that shutdowns for refractory maintenance can be a logistical and financial nightmare when up to $50,000 each day is on the line. However, downtime – and costs – can be reduced by employing specialized equipment that streamlines the installation process. If you’re ready to be ultra-efficient, read on. Bricking Machines The best [...]

Rise Above Downtime

It’s time to upgrade maintenance practices for vertical vessels with Bricking Solutions’ EZ Lift Suspended Platform. Like any routine maintenance, inspecting, removing and replacing refractory in pre-calciners, cyclones, lime kilns, ISAMELT furnaces and other vertical vessels places a costly burden on facilities in terms of downtime and lost productivity. One of the main reasons for [...]

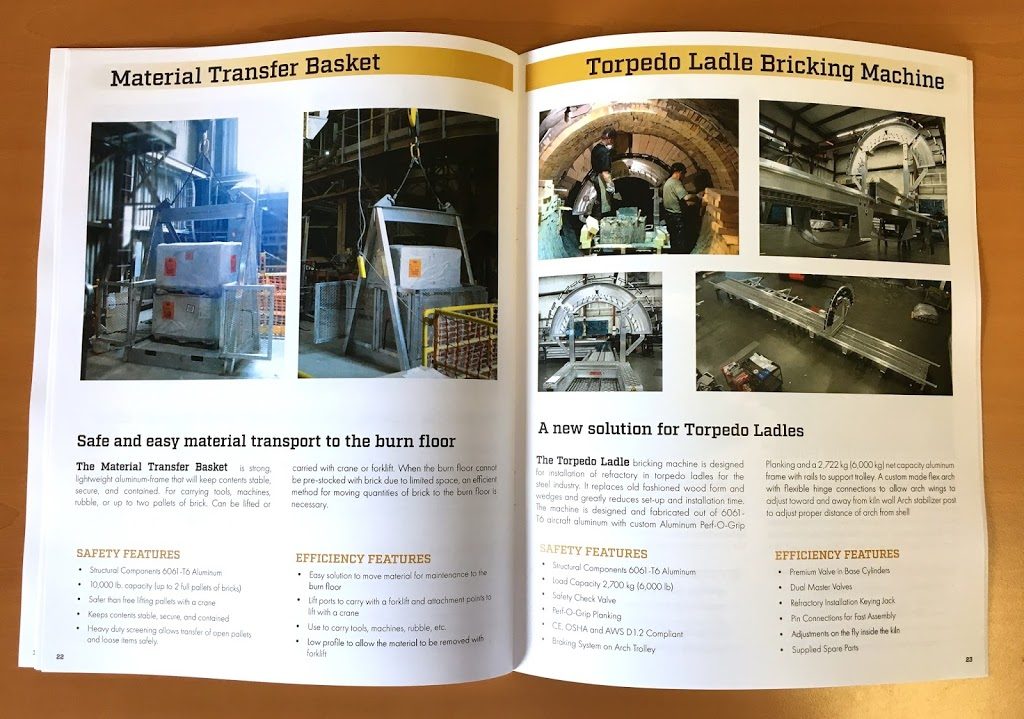

Bricking Solutions’ Torpedo Ladle

Improves Refractory Replacement Efficiency Bricking Solutions, a full solution provider of refractory installation equipment, offers the Torpedo Ladle Bricking Machine. This bricking machine replaces old-fashioned wood form and wedges and cuts set-up time in half. It also offers greater efficiency and safety for refractory installation in torpedo ladles. “Bricking Solutions designed the Torpedo Ladle [...]

3 Benefits of Custom Ramps

Kiln access ramps are the first equipment on site and the last to be removed when refractory maintenance is complete. They provide the only access across the cooler for crews, equipment and materials. They also have a significant impact on both productivity and safety. Working with an OEM for a custom kiln access ramp offers [...]

Bricking Solutions’ Brokk Cart Increases Demolition Robot Transportation Efficiency

Bricking Solutions, a full solution provider of refractory installation equipment, partners with parent company, Brokk, the world’s leading manufacturer of remote-controlled demolition machines, to offer the Brokk Cart. The wheeled cart improves efficiency when moving remote-controlled demolition robots across hard, level surfaces, such as those in a maintenance shop. The Brokk Cart provides operators and [...]

3 Tools for Efficient Brick Management

Efficient brick management is an important part of quality refractory installation. An ideal system will do three things – Decrease material handling. Handling leaves small nicks and chips in the brick surface, negatively impacting quality. Increase safety by minimizing the physical handling of refractory. This results in less strain on employees and fewer minor injuries [...]

New Bricking Machine Delivers Efficient, Ergonomic Brick Management

Brick management has a significant impact on overall refractory installation efficiency. Up kiln or down, having bricks delivered in a way that’s comfortable for you and your crew increases productivity and safety. To increase brick management options, we recently released a new Stair-Stepped Bricking Machine. The new model retains the key benefits of our EZ [...]

Bricking Solutions’ Stair-Stepped Bricking Machine Offers Extra Clearance

Bricking Solutions, a full solution provider of refractory installation equipment, introduces the Stair-Stepped Bricking Machine. The new model retains the key benefits of the company’s EZ Flexx50 Bricking Machine, which offers the lightest weight and highest load capacity on the market, but features a stair-stepped deck. This provides enough clearance beneath the scaffolding for forklift [...]

Big or Small – Specialized Equipment Maximizes Productivity for Your Kiln

From burn floor to access, every kiln is unique. So, shouldn’t your maintenance solution be, too? Here’s how to select the refractory maintenance equipment — such as kiln access ramps, conveyor systems and bricking machines — that fit your operation and process to maximize your productivity. Access Metal access ramps have the strength and durability [...]

Bricking Machine Benefits

Get work done up to two times faster with a bricking machine from Bricking Solutions. A pin-together design makes for fast and easy assembly — as fast as 60 minutes. Constructed out of aircraft-grade aluminum, the machine is as strong as steel, but weighs two-thirds less. Each bricking machine provides ample deck space for increased [...]

Key Considerations for Choosing a Bricking Machine

Not all bricking machines are equal. A thoughtfully designed machine made from quality material can significantly reduce downtime. We created this visual guide to illustrate key considerations.

Playing the Numbers

When to Repair or Replace Your Bricking Machine Equipment investment is always a numbers game. Having the right tools on hand at the right time is imperative for efficient operation. But does it need to be a brand-new machine? Or would repairs to key components provide the same productivity and safety with a smaller investment? [...]

Safety First

Selecting the Right Equipment to Optimize Refractory Safety and Productivity Chris Jones, Bricking Solutions Lead Engineer With refractory maintenance taking place annually in most facilities, making the right equipment choice not only increases productivity, it provides peace of mind in regard to worker safety. Throughout the entire process, from initial inspection to installation and final [...]

Refractory Safety Options That Come Full Circle

With advancements in kiln technology, size and applications, out-dated refractory lining installation techniques — such as pogo sticks or jack and timber — have slowly been replaced in factories and facilities around the world. Bricking materials have not changed much, but how contractors align, place and secure them has become safer and more productive than [...]

Bricking Solutions’ After Sales Services Maximize Uptime

Bricking Solutions, a full solution provider of refractory installation equipment, offers a number of after sales services to help operations maintain equipment to maximize uptime during refractory installation applications. Services include equipment evaluation, parts and repair, and refurbishment options. These services, paired with proper routine maintenance, provide a cost-effective measure for facilities and contractors, virtually [...]

Keep Bricking Along

Tips to Maximize Bricking Machine Longevity Refractory installation is a demanding application. Thankfully, Bricking Solutions has developed a full line of equipment to make the job easier — and safer — for crews. But harsh kiln environments still take a heavy toll on bricking machines and other equipment.

Bricking Machine Benefits for Improved Kiln Maintenance

Any mason will tell you, the key to effective refractory lining lies in quality brick installation. By minimizing air gaps and interlocking rings or loose bricks, the life of kiln lining is extended, and unscheduled or emergency maintenance can be drastically reduced, saving plants tens of thousands of dollars annually. To achieve high-quality installation as […]

Port-A-Trac Refractory Transport System Increases Efficiency and Safety

Bricking Solutions, a full solution provider of refractory installation equipment, offers its Port-A-Trac refractory pallet transport system for increased efficiency and safety during refractory installation applications. The Port-A-Trac offers customizable lengths and allows installation crews to transport full pallets of brick into the kiln and under the Bricking Machine easily and with minimal risk to […]

Sugar Producer’s Sweet Solution for Annual Maintenance

No matter the industry, annual maintenance can leave a sour taste. Keeping annual inspections and routine maintenance short and sweet is vital for overall efficiency — especially for operations like North America’s largest beet processing factory. So when the plant upgraded to a new 800-ton vertical lime kiln, it decided to look for an upgraded […]

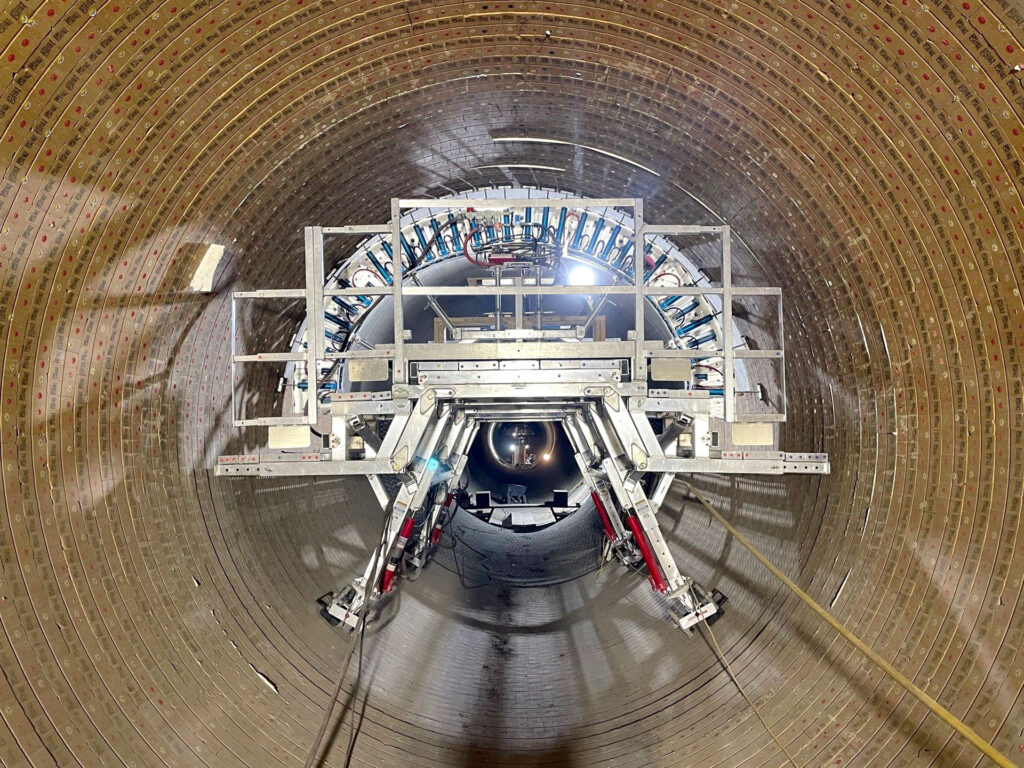

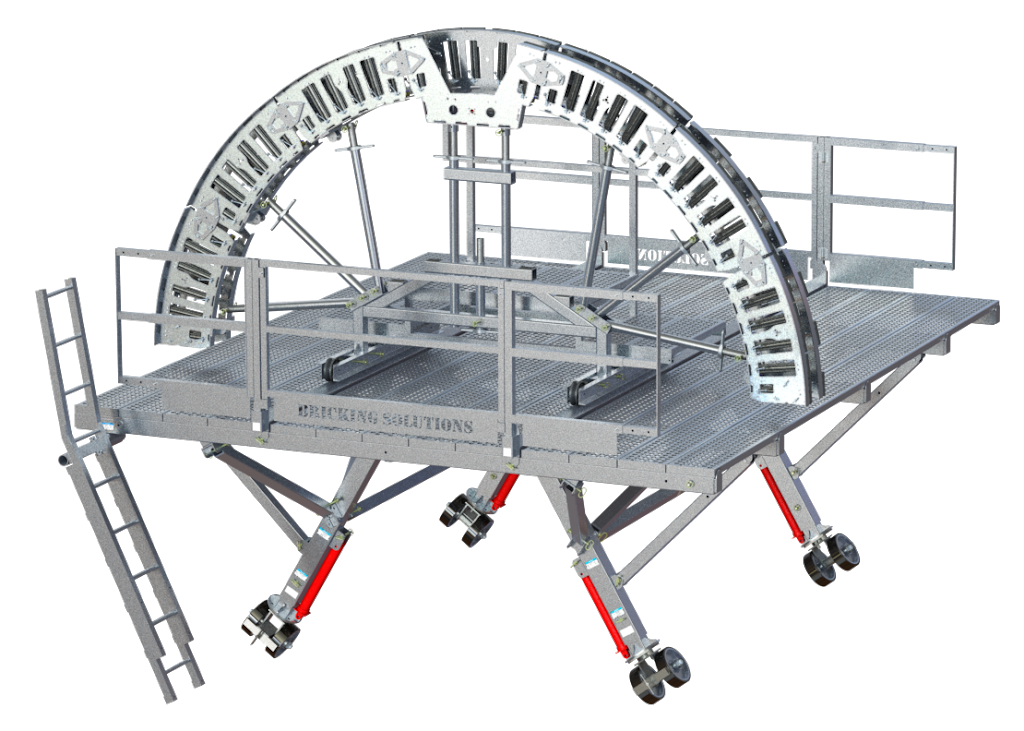

Bricking Solutions’ New Rolling Work Platform Offers 25% More Productivity

Bricking Solutions, introduces its Rolling Work Platform for improved safety and efficiency during maintenance of horizontal vessels. The platform offers 25% increased productivity over traditional rolling scaffolds and features a durable, custom-engineered design. It is used in a variety of applications including water treatment, tunneling and mining.

The Benefits of Aluminum on Your Bottom Line

Kiln maintenance can take its toll on your bottom line. Plant managers need reliable, efficient maintenance methods to get back up and running quickly and minimize profit-stealing downtime. That requires using the right equipment — made from the best materials.

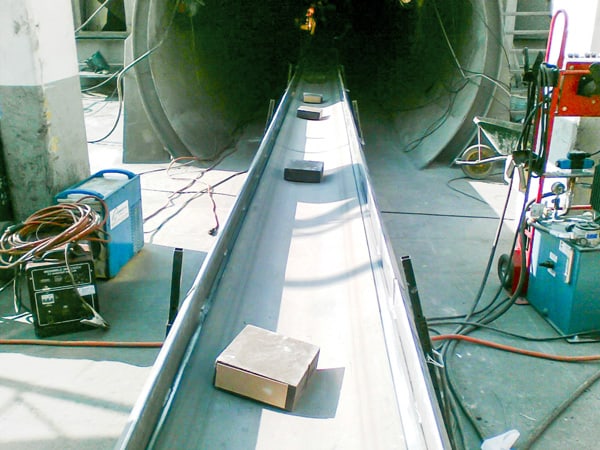

Reinforce Safety with Hydraulic and Incline Conveyors

Bricking Solutions, a full solutions provider in kiln refractory installation equipment, offers Hydraulic and Incline Conveyors to increase maintenance efficiency and reduce worker physical strain. Made from heavy-duty aluminum, these conveyors increase efficiency and safety, while minimizing damage to kilns and refractory materials during routine refractory maintenance.

Publication Articles

2019 Sugar Producer Finds Sweet Solution for Annual Maintenance World Cement, 2019 by Bricking Solutions 2018 The Key to Kiln Maintenance World Cement, 2018 by Heather Harding 2017 The Right Tool For the Job - improved efficiency in relining large rotary kilns World Cement, June 2017 by Eliane Taveira, TE&M Antidesgaste Brasil 2016 Reaching New [...]

OEM Kiln Access Ramps: Why Partner with a Pro

OEM Kiln Access Ramps: Why Partner with a Pro Kiln access ramps are an important part of safe, efficient kiln maintenance. Producing one in-house may seem cost efficient but poor design and lengthy installation often end up costing more in the long run. Partnering with a specialized manufacturer offers added benefits such as a custom […]

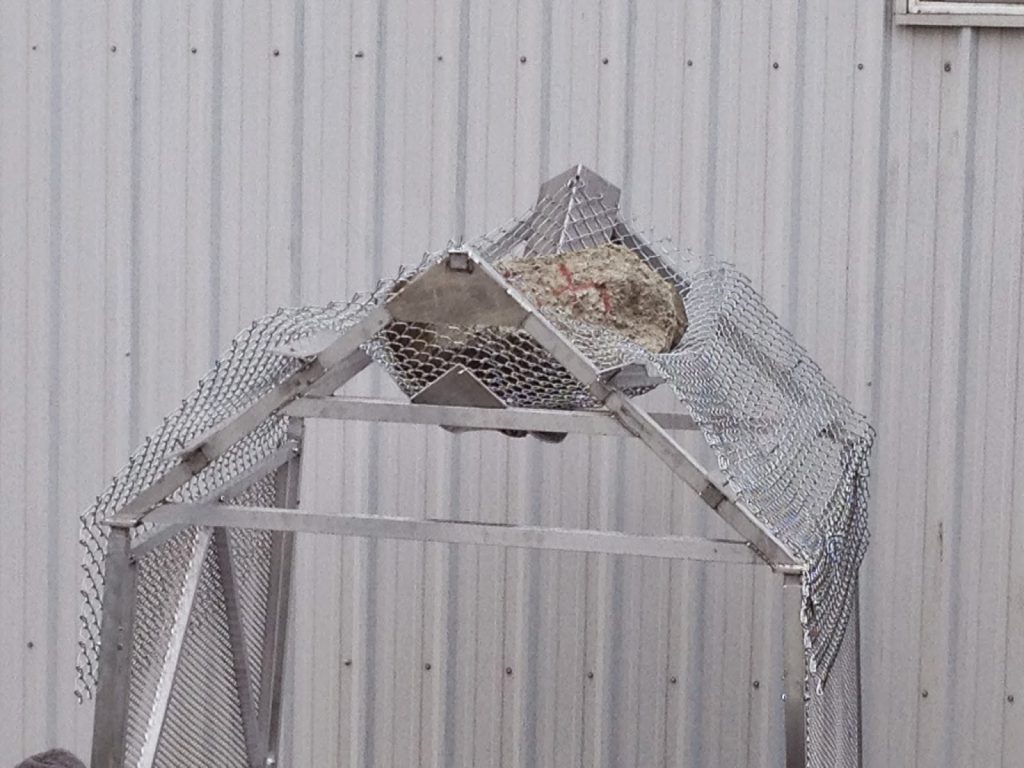

Increase Worker Safety with Inspection Cages

Lightweight Safety Solutions Kiln repair and maintenance are undoubtedly hazardous tasks, but kiln operators can take steps to provide additional protection for workers. Safety Inspection Cages provide heightened protection keeping them out of harm’s way from debris that commonly falls as coatings shrink and expand. These cages are lightweight, easy to operate and conveniently pair […]

Kiln Access Ramps Offer 40 Percent Faster Installation Time

Bricking Solutions, a full solutions provider in kiln refractory installation equipment, introduces Kiln Access Ramps to provide safe and easy access for maintenance personnel and equipment.

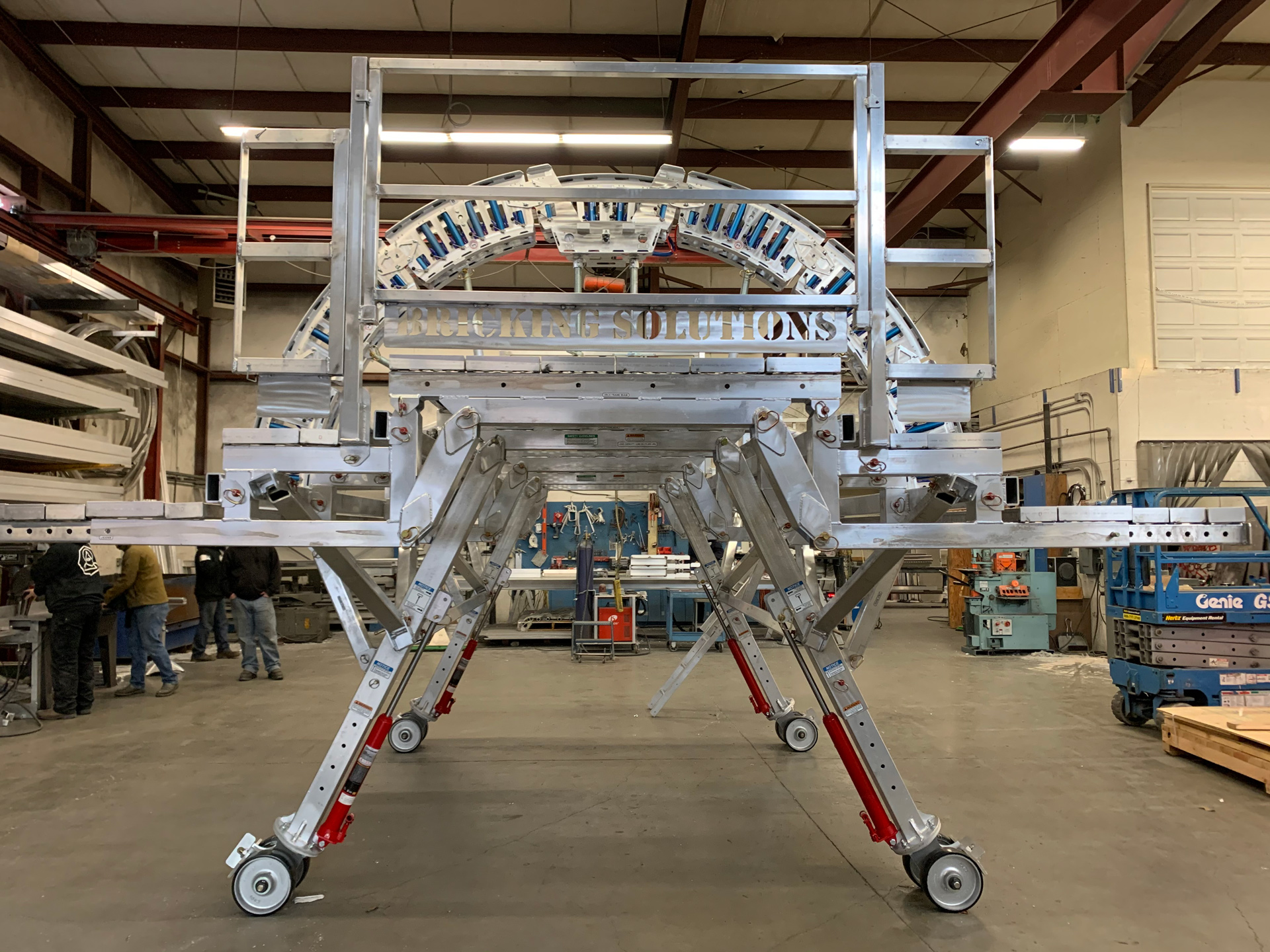

Lightweight, High Capacity Bricking Machines

Bricking Solutions, a full solution provider of refractory installation equipment, offers the Ez Flexx50 Bricking Machine. The largest version weighs 3,100 pounds (1,406 kilograms), making it one of the lightest

Revolutionizing Refractory, Brick by Brick

More than 50 years in the business has taught us what it takes to be industry leaders. We put the best of that knowledge into our Ez Flexx50 Bricking Machine, the lightest, strongest and safest refractory installation

Universal Safety Inspection Cage

Introducing the NEW Universal Safety Inspection Cage. Here at Bricking Solutions, we took our 16 years experience of engineering and manufacturing Safety Inspection Cages and incorporated the latest safety and design concepts to create a Safety Inspection Cage that is still the safest in the industry, but only weighs 64 kg!

Access is the First Consideration in Kiln Maintenance

Each burn floor is unique and every configuration is different. Here at Bricking Solutions, we understand that and have built 200 Custom Kiln Access Ramps to plants all over the world.

Small Size, Big Solution

Do you have a kiln 4M (13′) or smaller? Bricking Solutions has the right size bricking machine for your kilns from 4M all the way down to 1.5M. Our newest addition to our Bricking Machine line

Bricking Solutions Bricking Machine vs the Competition

BRICKING SOLUTIONS, Fig. 1: Ergonomic Cut-out section in front arch – Allows key mason room and keying access to close out row. Load Capacity: Standard 4000kg (8000 lb): 2 pallets of brick plus workers and tools. Optional 6000kg (13228 lb): 3 pallets of brick plus workers and tools. Optional small kiln 2722kg (6000 lb):1 pallet […]

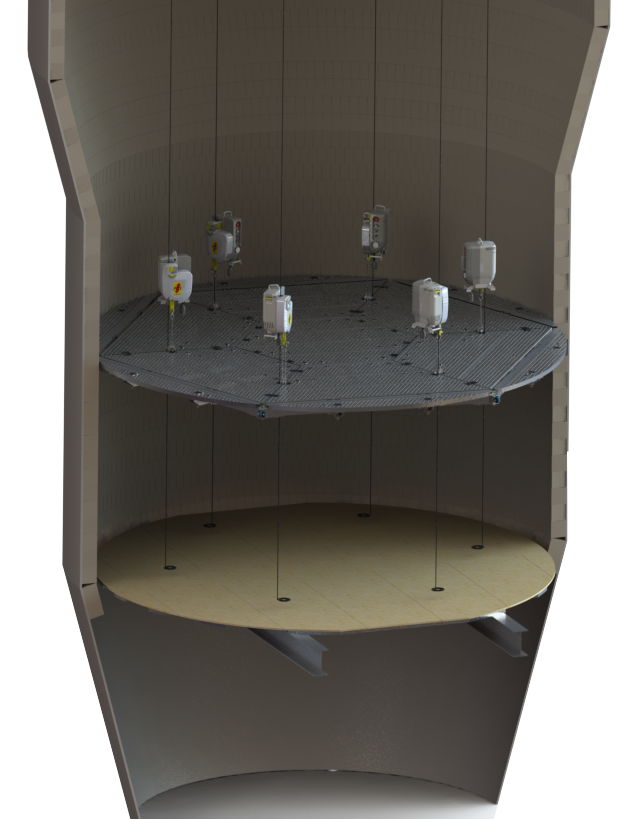

Taking You to New Heights

Did you know that Bricking Solutions builds platforms for Isamelt Furnaces? Here is our recent order to Kansanshi Mining which includes a custom Ez Lift Suspended Platform built for 3 different sizes. Suspended by a trolley that spans the length of beams enables the platform to move into a different sections of furnace.

The World Leader in Refractory Maintenance Products

We are the world leader in Refractory Maintenance Products and we have been manufacturing equipment for cement kilns since 1967.

Introducing our Newest Bricking Machine – The Ez Flexx50 – Lightest Machine In the Industry

It is with much pride that Bricking Solutions introduces their newest bricking machine, the EZFlexx50.

Kiln Safety – Protect Yourself from Falling Coating

Bricking Solutions, Inc has been building Refractory Maintenance Equipment for over 40 years. It’s all we do. We don’t only make bricking machines but a wide variety of other equipment to support your kiln. We have been building our Safety Inspection Cages for over 17 years and have sold over 150 cage systems! Selling to […]

Hydraulic Conveyor for Material Handling

Bricking Solutions makes a wide variety of products for Refractory Maintenance. It is all we do. One product that we have been manufacturing for 15 years is our Hydraulic Conveyor System. The Conveyor System not only brings refractory into the kiln when fork truck access is limited but can also be used for removing debris [...]

EZLift Suspended Platform

We have designed and tested and re-designed for a new and improved Suspended Platform. Bricking Solutions has been manufacturing refractory maintenance products for over 40 years and the Suspended Platform is the Safest, most Effective work access in vertical vessels. Watch this quick video to learn more! Ez Lift Platform Video The suspended platforms are […]

Successful Bricking Solutions Training

We had a successful training at Bricking Solutions. Visitors from Holcim Trident – MT, Ash Grove Cement Leamington – UT, and Argos Cement Calera – AL were present. We went over replacing and trouble shooting parts on both our old MOR and our new Ez Flexx Bricking Machine as well as the new machines safety […]

Ultratech Rawan Kiln 2 Successful commissioning of their Kiln Access Ramp

Ultratech Cement Ltd, Rawan Plant, 10,000 tpd KHD Kiln 2 – Successfully commissioned their new Kiln Access Ramp.

We are the Industry Leader in Safety Inspection Cages

Bricking Solutions has been manufacturing Safety Inspection Cages and Personal Protection Tunnels for 15 years. We rigorously test all our cage designs and they meet industry safety standards. Allows personnel, material and equipment to move safely inside your kiln 1.5M (5 feet) of portable protection designed & certified by a professional engineer. Rated for 114kg […]

Maintenance Solution for Cement Plant Preheat Tower Vessels

Maintenance work in preheat tower vessels (cyclones, risers and pre-calcinator) is not only difficult and time consuming but can be a dangerous task.

Bricking Solutions Custom Bedding Cart

The Bedding Cart not only allows for the movement of bedding refractory as the bedding process progresses, but provides stair steps to facilitate the placement of refractory to or just above the spring line on larger kilns. Congratulations to Ultratech Cement – Kotputli Works for their new Custom Bedding Cart. When bedding out the bottom […]

Vertical Lime Kiln Utilizes New Suspended Work Platform

A unique solutions to refractory maintenance on a vertical kiln, borrowing an example for the sugar industry.

J.T. Thorpe & Son, Inc receive an Econ-O-Ring and 200′ Long Hydraulic Conveyor

Thank you J.T. Thorpe & Son, Inc for your order of the Econ-O-Ring Bricking Machine and the 12″ wide by 200′ long Hydraulic Conveyor system.

Work From the Bottom

Keith Post, Bricking Solutions, talks us through his wealth of experience on matters of proper refractory installation. The kiln is down again. These are five words guaranteed to make people cringe with thoughts of added expense to the yearly budget, lost production and safety concerns due to another unplanned outage. Questions are asked, and doubts […]

Torpedo Ladle Bricking Machine

Did you know we also manufacture custom brick lining machines for torpedo ladles? Our most recent custom machine was for Zapadno Sibirskiy Metallurgical Combinat – West Siberian Steel Works (ZSMK) Russia. This bricking machine is designed for installation of refractory bricks in torpedo ladles for the steel industry. Replaces old fashion wood form and wedges. […]

Shurovsky Cement, Holcim Russia, receives new Mini Econ-O-Ring Bricking Machine

Thank you and congratulations to Shurovsky Cement, Holcim Russia in the Moscow Region and Hoganas AB Bjuf for their order of a new Mini Econ-O-Ring (MECOR)

All Bricking Machines are NOT Created Equal

Who is Bricking Solutions and why are our products better than the rest?

Fork Truck Bracket

Utilizing a fork truck, you can easily transport a completed arch or set of machine frames in and out of kiln The use of a fork truck bracket enables the arch and frames to be moved without being disassembled, saving time during each use With arch turned parallel to fork truck and kiln, and bracket […]

Brick Lining Equipment for Ambuja Cement – Rabriyawas Works

Thank you and congratulations to Ambuja Cement Limited – Rabriyawas Works for their order of a Premium Ez Flexx EOR Bricking Machine, Kiln Laser Target and Burner Alignment, and Fork Truck Bracket. Thank you also to The Consultants for your hard work!

Custom Ramp Tunnel Cage System for Titan Cement

Thank you and congratulations to Titan Cement Company Greece for their new Ramp Tunnel Cage System and Refraconsulting for your hard work. This product is similar to our Personal Protection Tunnel but this was custom designed for Titan Cement’s preexisting ramp. The system is designed to cover the entire bridge section of the ramp that […]

Proper refractory staging for efficient and safe refractory installation

The number one reason for slow bricking times is slow supply of brick to the masons. Every plant has different obstacles such as: limited access, small burn floor, small kiln diameter, or the location of the job. Replacement of brick could be down in the cooler or way up in the intake section of the […]

Refractory Installation Equipment Care

The following is an excerpt from Stacey Rice, BBS Service manager, and her response to our agent’s service report and follow up request on how their customer can reduce maintenance costs

Safety Inspection Cages for Lafarge Spain

Congratulations to Lafarge Spain and Thank you Anzeve for 3 Bricking Solutions Safety Inspection Cages.

Kiln Access Ramp for TXI Hunter Cement

Congratulations TXI Hunter Cement – Texas, USA and Thank You to Southern Refractories – Texas, USA for their order of a new Kiln Access Ramp.

Turkish cement industry continues to grow even though to the global economic crises.

The clinker capacity exceeded 64 million ton and cement capacity exceeded 105 million ton in Turkey with 48 integrated plants and 20 grinding stations as of 2010. If we consider the figures of 2009, Turkey is the biggest cement producer in Europe and the 5th in the world. Safety Somer International, an agent in Turkey […]

Re-joining with Tianjin Pfister

Bricking Solutions and Tianjin Pfister have re-joined forces. Tianjin Pfister has been appointed exclusive distributor for Bricking Solutions for China. Tianjin Pfister’s 21 strong sales force will be trained at Tianjin Pfister’s newest manufacturing plant in Tianjin. In addition to audio visual equipment, meeting rooms and Bricking Solutions literature translated into Mandarin, Tianjin Pfister has […]

Kiln Bedding Cart

Tired of using spring boards or crates to install your refractory to spring line or in reality as high as gravity will allow when bedding your kiln? Take a look at a 21st century solution a custom bedding cart.

Double the Productivity

Bricking Solutions announces twin bricking machines capable of bricking from 3.8m kiln ID to 6m kiln ID. These talented machines not only adjust from 3.8m kiln ID to 6m kiln ID, but are able to adjust easily in the kiln on the fly to make bricking though tapers and conical sections a breeze. They are […]

Incline Transport Conveyor

Bricking Solutions has a new product! Our Incline Conveyor transports refractory from the kiln floor to the bricking machine work platform This product is a perfect solution if there is no access for a fork lift to enter the kiln. Like our other conveyors, the Incline Conveyor is made out of lightweight high quality aluminum […]

Largest Machine Ever

Bricking Solutions is delivering the largest fully adjustable EZ FLEXX bricking machine ever built to LKAB mining located in Kiruna, Sweden. This machine will have a range of 5.5m to 7.5m to work in their two 5.5-6.1m kilns, their 6.7m kiln and their 6.8-7.5m kiln, with the ability to adjust through the conical sections on […]

Improving Kiln Uptime

The kiln is considered the heart of a cement plant and its performance happens to be the deciding factor for the total profitability of the plant.

Bedding Cart

Bricking Solutions knows that efficient handling of refractory can make or break a relining project. The Bedding Cart not only allows for the movement of bedding refractory as the bedding process progresses, but provides stair steps to facilitate the placement of refractory to or just above the spring line on larger kilns.

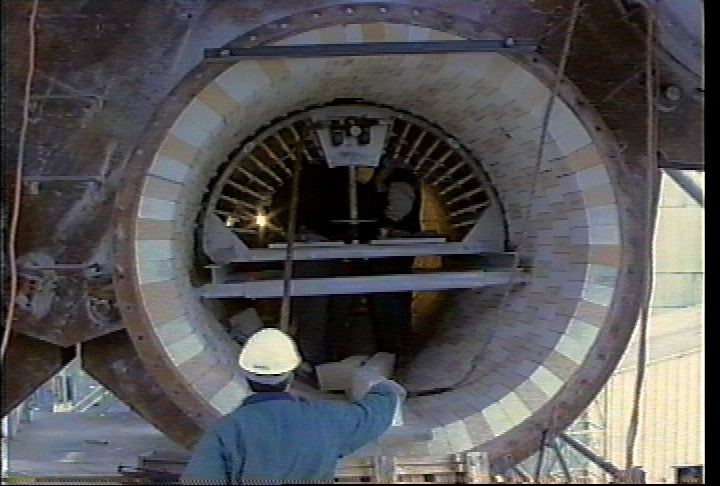

Bolt together Bricking Rig for a furnace with limited access

It is always gratifying to receive a message like the one below. Bricking Solutions lived up to its name by solving a limited access issue (48” man access port) along with the challenge of furnishing a large adjustable machine for multiple diameter (16” and 19” Brick I D), multi brick layer cylindrical furnace in a […]